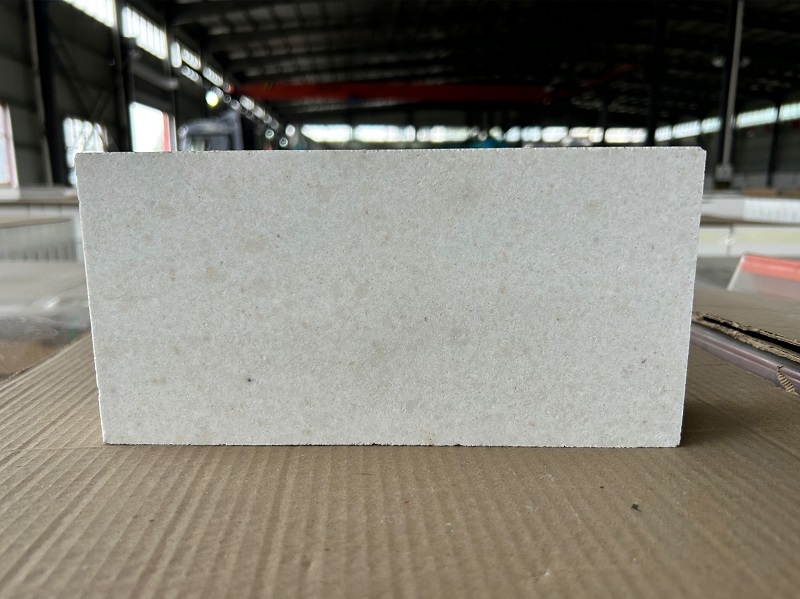

Sintered AZS bricks

Classification:

Product Introduction

Sintered AZS brick is a refractory material that is mainly composed of alumina (Al2O3), zirconia (ZrO2), and silicon dioxide (SiO2), the acronyms of these elements that make up the name AZS.

Sintered AZS brick is a refractory product made of zircon and alumina as the main raw materials and pre-synthetic materials as aggregates. This kind of brick has the characteristics of high strength, high temperature resistance, erosion resistance and good chemical stability

Due to its good mechanical properties at high temperature, sintered AZS bricks are widely used in metallurgy, building materials, petroleum, chemical industry, ceramics, glass, enamel, carbon black, non-ferrous metals and other industrial kilns. Especially in glass furnaces, AZS bricks are often used in critical parts of glass furnaces, such as the bottom of the tank, the wall of the tank, the superstructure and the forehearth, which are often eroded and corroded by the material.

| Projects | Physical and chemical indicators | ||||

| AZS16 | AZS20 | AZS32 | |||

| chemistry ingredients | (ZrO2)/% | ≥ | 16 | 20 | 32 |

| (Fe2O3)/% | ≤ | 0.5 | 0.5 | 0.5 | |

| physics performance | Bulk density/(g/cm3) | ≥ | 2.70 | 2.80 | 3.20 |

| Apparent porosity/% | ≤ | 20 | 18 | 18 | |

| Compressive strength/Mpa | ≥ | 70 | 80 | 80 | |

| Load softening temperature T0.6/°C | ≤ | 1580 | 1620 | 1630 | |

Key words:

Sintered AZS bricks

Related Products

Product inquiry