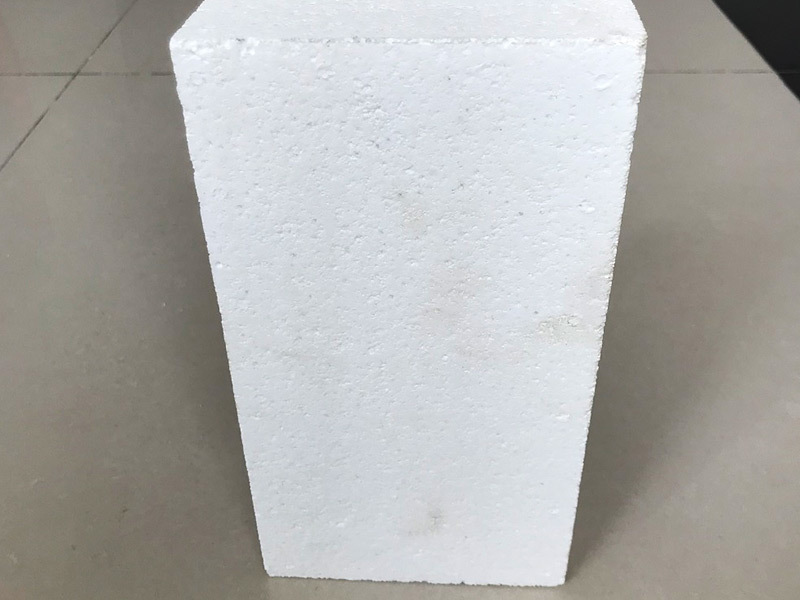

Corundum bricks

Classification:

Product Introduction

Corundum bricks are aluminium-silicon refractory products with corundum as the main crystalline phase, and corundum bricks are divided into three types: fused corundum bricks, fused corundum re-sintered bricks, and sintered corundum bricks. Melting and casting corundum bricks is to melt industrial alumina and a small amount of soda ash and quartz powder in an electric arc furnace, and then go through casting, annealing and other processes, and finally mechanical processing into the required shape and size. Fused corundum re-sintered bricks are made of crushed fused corundum particles and fine powder, adding a small amount of clay and binder, and forming with a brick press after full mixing. The density of bricks is 2.75~2.85g/cm3, and the bricks are fired at 1700~1800 °C after drying.

Corundum bricks have a series of excellent properties, high mechanical strength and high hardness. In addition, it also has good wear resistance, oxidation resistance, corrosion resistance and electrical insulation properties.

| Projects | Physical and chemical indicators | ||||

| GYZ-99A | GYZ-99B | GYZ-98 | GYZ-95 | ||

| (Al2O3)/% | ≥ | 99 | 99 | 98 | 95 |

| (Si02)/% | ≤ | 0.15 | 0.2 | 0.5 | / |

| (Fe2O3)/% | ≤ | 0.10 | 0.15 | 0.2 | 0.3 |

| Apparent porosity/% | ≤ | 19 | 19 | 19 | 20 |

| Bulk density/(g/cm3) | ≥ | 3.20 | 3.15 | 3.15 | 3.10 |

| Compressive strength at room temperature/Mpa | ≥ | 80 | 80 | 80 | 100 |

| Permanent line change of heating (1600°C×3h)/% | Xmin Xmax | -0.2~+0.2 | -0.2~+0.2 | -0.2~+0.2 | -0.3~+0.3 |

| Load softening temperature (0.2Mpa, 0.6%)/°C | Xmin | 1700 | 1700 | 1700 | 1700 |

Key words:

Corundum bricks

Fused corundum bricks

Sintered corundum bricks

Fused corundum and then sintered bricks

Related Products

Product inquiry