Low creep clay bricks

Classification:

Product Introduction

Low creep clay brick is a refractory with superior properties and a low creep rate, which means that under high temperatures and constant pressure, this type of brick has less deformation and shape change. Here are some key information about low creep clay bricks:

1. Definition: Low creep clay bricks refer to fired clay products with low creep rate.

2. Classification: According to the GB/T 34188-2017 standard, low creep clay bricks are divided into DRN-128A, DRN-128B, DRN-125, DRN-120, DRN-115, DRN-110, DRN-105 according to physical and chemical indicators.

3. Material properties:

Structural stability: Low-creep clay bricks are more likely to retain their original shape and size, thus maintaining the overall stability of the furnace or kiln structure.

Extended service life: Low creep rate helps refractory bricks retain their properties for longer, thus extending the life of the material.

Furnace protection: In high-temperature industrial equipment, a low creep rate helps reduce deformation and extrusion of the refractory lining, extending furnace life, reducing maintenance costs, and avoiding the need for frequent replacements.

4. Application: Low creep clay bricks are widely used in metallurgy, building materials, chemical industry, petroleum, machinery manufacturing, silicate, power and other industrial fields, and are widely used in hot blast stoves. It is especially suitable for supporting hot blast stoves of large, medium and small blast furnaces, and is mainly used in the middle and lower walls, lower lattice bricks, supporting chords and other parts of heat storage.

5. Technical requirements: The technical requirements of low creep clay bricks include chemical composition, apparent porosity, compressive strength and creep rate at room temperature, etc., and the specific values vary according to different grades.

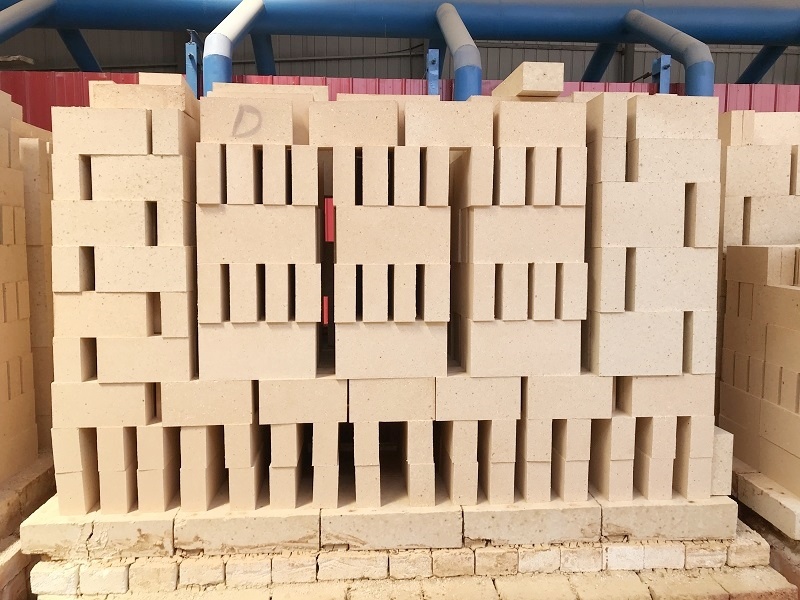

6. Production process: Low creep clay bricks are made of super-grade bauxite clinker as the main raw material, supplemented by special additives, and are formed by high pressure molding and high temperature firing, which has the advantages of large heat storage capacity and small creep rate.

These characteristics make the low creep clay brick have good stability and reliability in high temperature environment, and are suitable for various high temperature kiln and industrial furnace applications.

| Projects | Physical and chemical indicators | |||||||

| DRN-128A | DRN-128B | DRN-125 | DRN-120 | DRN-115 | DRL-110 | DRL-105 | ||

| (Al₂O₃)/% | ≥ | 45 | 45 | 45 | 42 | 40 | 36 | 32 |

| (Fe₂O₃)/% | ≤ | 1.5 | 4.8 | 1.5 | 1.8 | 1.9 | 2.0 | 2.0 |

| Apparent porosity/% | ≤ | 15 | 18 | 20 | 20 | 22 | 22 | 22 |

| Compressive strength at room temperature/Mpa | ≥ | 60 | 55 | 45 | 35 | 35 | 30 | 25 |

High temperature flexural strength/Mpa (1200°C,0.5h) | ≥ | 6 | 5 | / | / | / | / | / |

| Creep rate/%(0.2Mpa,50h) | ≥ | 1280℃×25h 0.25 | 1280℃×25h 0.4 | 1250℃ 0.8 | 1200℃ 0.8 | 1150℃ 0.8 | 11100℃ 0.8 | 1050℃ 0.8 |

| Heating Permanent Line Change % | U-L | 1400℃×2h -0.3~0.1 | 1350℃×2h -0.4~0.1 | 1300℃×2h -0.4~0.1 | ||||

Key words:

Low creep clay bricks

clay bricks

Related Products

Product inquiry