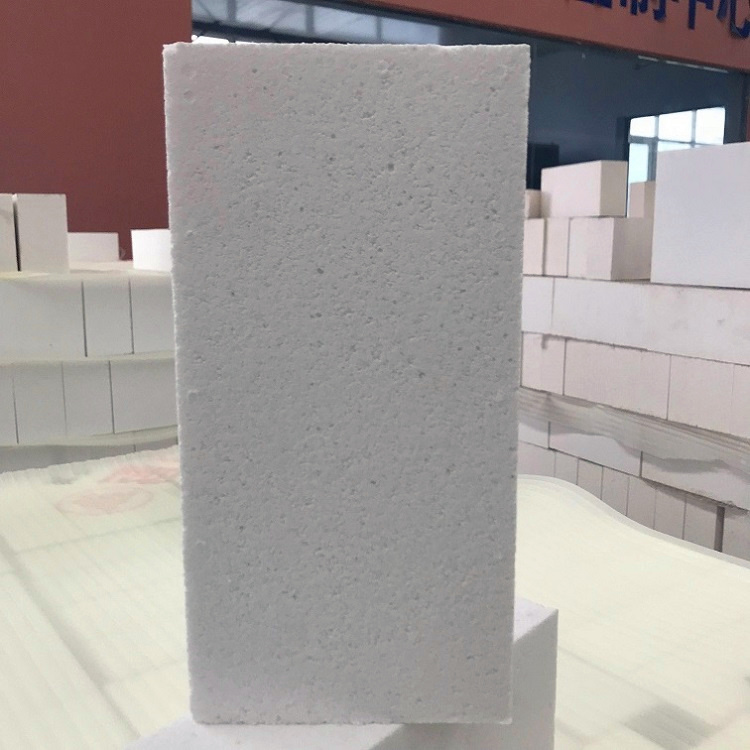

Alumina hollow ball bricks

Classification:

Product Introduction

Alumina hollow ball brick is made of alumina hollow ball and α-Al2O3 powder as the main raw materials, which are fired at high temperature after moulding and drying, with an Al2O3 content of more than 90% and a main crystal phase of α-Al2O3 (corundum). Here's a closer look at it:

1. Performance characteristics of alumina hollow ball bricks:

High temperature resistance: It has high refractoriness, the maximum operating temperature can reach about 1800 °C, good thermal stability, small change of re-sintering line, and can maintain stable performance in high temperature environment.

Excellent thermal insulation performance: the hollow ball structure makes its bulk density small, generally 1.3-1.8g/cm³, only about half of corundum products, low thermal conductivity, can effectively reduce heat transfer, play a good role in thermal insulation, and the energy-saving effect can reach more than 30%.

Good thermal shock resistance: in the case of rapid temperature changes, it is not easy to crack or be damaged due to thermal expansion and contraction, and can adapt to the fluctuation of temperature in the kiln.

High mechanical strength: Although it is a light refractory material, the mechanical strength of the product is relatively high, several times that of general light products, and it can withstand certain mechanical stress.

2. Alumina hollow ball brick production process:

Preparation of alumina hollow balls: industrial alumina is used as raw material, melted by electric melting method and then sprayed. When the temperature of the solution reaches or higher than 2200 °C, the furnace body is tilted to make the melt flow out, and at the same time, the molten stream is sprayed with compressed air, and under the action of the molten viscosity and surface tension, a hollow ball wrapped in air is formed, which is stored separately according to different particles after collection and screening.

Manufacturing alumina hollow ball bricks: alumina hollow balls, sintered alumina fine powder and binder are batched and mixed evenly according to a certain proportion, and the bricks are made into bricks by vibration moulding and other moulding processes, and the bricks are fired at a high temperature of 1500 - 1800 °C after drying, or they can be prepared without firing to obtain a finished product without firing, and the furnace lining is directly constructed with amorphous materials.

3. Application range of alumina hollow ball bricks: widely used in high-temperature kilns in metallurgy, chemical industry, glass, ceramics, refractory and other industries. For example, heating furnaces and annealing furnaces in the iron and steel metallurgical industry; reactors in the chemical industry; In kilns such as firing kilns in the ceramic industry, it can be used as a working layer or thermal insulation layer in direct contact with the flame.

4. Physical and chemical indexes of alumina hollow ball bricks:

Alumina content: According to different grades and use requirements, the general alumina content (Al₂O₃) is 90% and above, and the common ones are 90%, 95%, 99% and so on.

Impurity content: impurities mainly include silicon dioxide (SiO₂), iron oxide (Fe₂O₃), etc., and their content needs to be controlled within a certain range, such as iron oxide content usually does not exceed 0.2% - 0.3%, and silica content varies according to different grades.

Bulk density: between 1.3 - 1.9 g/cm³, depending on the product grade and production process.

Load softening starting temperature: generally above 1650°C, higher grades of products load softening starting temperature can reach 1700°C and above.

Compressive strength at room temperature: usually above 10MPa, different grades and specifications of products are different.

Change of reburning line: Under the condition of 1600°C×3h, the change rate of reburning line is generally controlled within ±0.3%.

Thermal conductivity: At an average temperature of 800°C, the thermal conductivity is relatively low, generally not exceeding 1.8W/(m·K).

5. Energy-saving effect of alumina hollow ball bricks:

The lightweight nature of alumina hollow ball products helps to reduce the overall weight of the furnace body, reduce the heat capacity, reduce the ramp-up time, and reduce the energy consumption during start-up and heating.

Due to its low thermal conductivity and light weight characteristics, alumina hollow ball products have excellent thermal insulation performance, which can be used as the lining of high-temperature furnaces or as an insulation layer, which significantly improves the thermal insulation effect of furnaces, reduces heat loss in furnaces, and improves thermal efficiency.

In practical application, alumina hollow ball products can significantly reduce the fuel consumption of high-temperature industrial kilns, and the energy saving effect can reach more than 30%.

In summary, alumina hollow ball bricks have become an important refractory material due to their high temperature stability, light weight characteristics, thermal insulation properties, and wide application in many industrial fields.

| Projects | Physical and chemical indicators | |||||||||

LQZ- 99-1.4 | LQZ- 99-1.6 | LQZ- 99-1.8 | LQZ- 95-1.4 | LQZ- 95-1.6 | LQZ- 95-1.8 | LQZ- 90-1.4 | LQZ- 90-1.6 | LQZ- 90-1.8 | ||

| (Al2O3)/% | ≥ | 99 | 95 | 90 | ||||||

| (Si02)/% | ≤ | 0.3 | / | / | ||||||

| (Fe2O3)/% | ≤ | 0.2 | 0.2 | 0.2 | ||||||

| Bulk density/(g/cm3) | 1.3~ 1.5 | 1.5~ 1.7 | 1.7~ 1.9 | 1.3~ 1.5 | 1.5~ 1.7 | 1.7~ 1.9 | 1.3~ 1.5 | 1.5~ 1.7 | 1.7~ 1.9 | |

| Compressive strength at room temperature/Mpa | ≥ | 6 | 10 | 12 | 8 | 12 | 16 | 10 | 14 | 18 |

Thermal conductivity (hot surface 1000°C)/[W/(m. K)] | ≤ | 0.9 | 1.1 | 1.2 | 0.9 | 1.1 | 1.2 | 0.9 | 1.1 | 1.2 |

| Permanent line change of heating (1600°C×3h)/% | -0.3~+0.3 | -0.3~+0.3 | -0.3~+0.3 | |||||||

Key words:

Alumina hollow ball bricks

Related Products

Product inquiry